Introduction to IoT in Industrial Automation

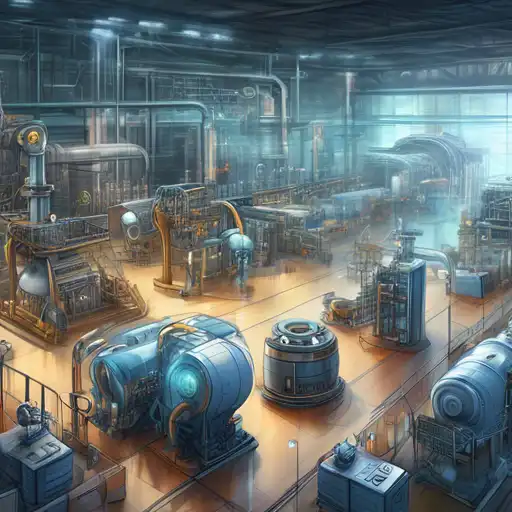

The Internet of Things (IoT) is transforming industrial automation by enabling smarter, more efficient manufacturing processes. By connecting machines, devices, and sensors to the internet, businesses can achieve unprecedented levels of operational efficiency and productivity.

How IoT is Changing the Game

IoT technology allows for real-time monitoring and control of industrial equipment, leading to significant improvements in performance and maintenance. This connectivity not only reduces downtime but also enhances safety and energy efficiency.

Key Benefits of IoT in Industrial Automation

- Enhanced Efficiency: Automated systems can adjust operations in real-time based on data analytics, optimizing performance.

- Predictive Maintenance: IoT devices can predict equipment failures before they occur, saving costs and time.

- Improved Safety: Remote monitoring reduces the need for human intervention in hazardous environments.

- Energy Savings: Smart systems can significantly reduce energy consumption by optimizing operational hours and processes.

Challenges and Solutions

Despite its benefits, integrating IoT into industrial automation comes with challenges such as security risks and high initial costs. However, advancements in cybersecurity and scalable IoT solutions are making it more accessible and secure for industries of all sizes.

Future Trends

The future of industrial automation lies in the further integration of IoT with technologies like artificial intelligence (AI) and machine learning (ML), paving the way for fully autonomous factories and smart manufacturing ecosystems.

Conclusion

The impact of IoT on industrial automation is profound, offering businesses the tools to innovate, compete, and thrive in the digital age. As technology continues to evolve, the possibilities for industrial automation are limitless.

For more insights into how technology is shaping industries, explore our articles on Smart Manufacturing and Industry 4.0.